Years of concentration

Advertising aluminum profile

The manufacture of advertising aluminum extrusion processing profile molds is also one of the key factors determining its quality service life. Because aluminum extrusion tooling has a series of characteristics, it requires very high requirements for aluminum profile mold making technology:

(1) Because the working conditions of aluminum alloy extrusion processing molds are very harsh, they need to withstand the effects of high temperature, high pressure high friction during the extrusion process. Therefore, high-strength heat-resistant alloy steel is required. Forging, heat treatment, electrical machining, machining surface treatment are very complicated processes, which brings a series of difficulties to the mold processing.

(2) In order to improve the service life of the aluminum extrusion extrusion die ensure the surface quality of the product, the roughness of the working cavity of the mold cavity must be 0.8-0.4 μm, the roughness of the mold plane must be less than 1.6 μm. Special polishing techniques polishing equipment are required when moulding.

(3) Due to the development of extruded products in the direction of high, precision sharpness, the wall thickness of some profiles pipes is reduced to about 0.5mm, the tolerance of extruded aluminum products is required to reach ± 0.05mm. High-precision products require mold manufacturing accuracy of 0.01mm, which cannot be manufactured with traditional technology. Therefore, it is required to update the technology use new special equipment.

(4) The cross section of advertising aluminum profiles is very complicated, especially for ultra-high precision thin-wall hollow aluminum profiles porous hollow-wall aluminum profiles, which require a special extrusion mold structure, often have multiple shaped holes in a mold at the same time. The thickness of the cavity each section changes drastically, the relevant dimensions are complicated, the arc corners are many, which brings a lot of trouble to the processing heat treatment of the mold.

(5) There are many types of advertising aluminum extrusion products, small batches, frequent mold changes, strong adaptability of the mold. Therefore, it is required to improve the production efficiency of the mold, shorten the mold cycle as much as possible, change the system quickly. The mold program can accurately produce a qualified mold according to the drawing, reducing the workload of mold repair to a lower level.

In summary, the processing technology of the aluminum extrusion extrusion die is different the general mechanical manufacturing process, but a special technology that is very difficult covers a wide range. In order to manufacture high-quality long-life molds, in addition to selecting preparing high-quality mold materials, it is necessary to formulate reasonable cold working processes, electrical processing processes, heat treatment processes surface treatment workers.

Mobile phone: Mr. Yao: 151-3363-1133

Landline: 0757-88048677

Email: 731731188@qq.com

Guozong Aluminum

Address 1: zhifangkou bridge, Zoushi Town, Taoyuan County, Changde City, Hunan Province

Address2: No. 28, North of Chatian Street, Shishan Town, Nanhai District, Foshan City

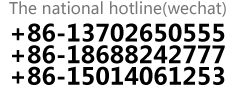

Scan, WeChat Consulting