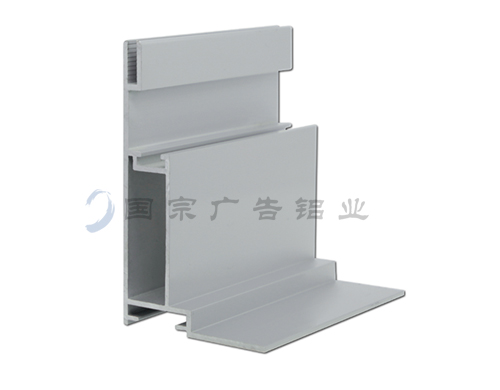

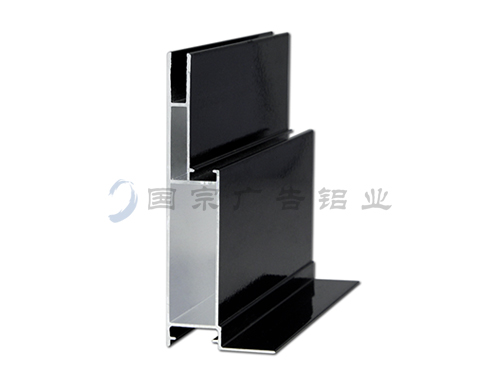

Years of concentration

Advertising aluminum profile

Some aluminum alloy products in the advertising aluminum processing production process also require subsequent aluminum profile processing, such as wire drawing, anodizing, etc., especially during stamping production, it is easy to cause top injuries scratches. Pay special attention to the following points in mold manufacturing:

1. For the case that the number of projects is affected, try to arrange the punching in the back of the project as much as possible, even for the products with a large number of punching, you can consider doing another project also punch the punching in the back.

2.The aluminum material is soft the mold is easy to block material, so when designing the mold to put the gap, it should be placed with a gap of 10% of the thickness of the bilateral material.The straight deep position of the knife edge is 2MM, the taper is 0.8-1 °.

3. When aluminum profiles are processed bent, the aluminum material is prone to produce aluminum shavings during bending, which can cause point injuries indentations. The aluminum raw material needs to be attached with a PE film. In the case of rollers electroplating, the forming block is polished. Hard chrome plating is preferred.

4. For stamping parts that need to be processed after anode, if the flattening flattening process is 180 °, the product cannot be completely pressed. The full pressing will cause acid spitting, a seam of 0.2-0.3MM should be left in order to make the acid solution smooth. It flows out in time, so it is necessary to make a stop block in this process the calibration mold is higher than the mold.

5.Because the aluminum material is brittle easy to crack, especially in the case of reverse folding, try to make the crimping line.Even if you want to do it, make the crimping line wider lighter.

6.All aluminum blades require slow wire cutting to prevent burrs blanking.Aluminum parts are prone to high temperatures. Therefore, the hardness of the punch must be above 60 °, at least SKD11 no D2. Aluminium material is relatively soft, so it is easy to produce top injuries, crush injuries, scratches, deformation during stamping production.In addition to the requirements on the mold, the following points must be achieved during stamping production:

1.If you want to punch aluminum parts well reduce the defect rate, you must first do 5S, especially clean, including the mold, punch table, assembly line packaging materials must be free of sharp debris, no dirt clear regular rectification, Both the top bottom of the mold must be cleaned without debris.

2.If the product has a large burr, it must be sent to the mold for repair in time follow up with the result.

3.Aluminum parts are more likely to generate heat, the backlog will harden, so you need to apply some oil on the material when punching cutting (you can dissipate the heat smooth the blanking), then punch.

4. For products with a lot of punching, it is necessary to clean the surface of the mold to ensure that the mold the product are always clean free of debris, reduce the top injury. If the top injury is found, the problem of the mold top injury must be found resolved before proceeding. produce.

5.Flattening the mold pushing block will produce aluminum shavings, so the aluminum shavings under the pushing block must be cleaned every day after the pushing block is produced.

Mobile phone: Mr. Yao: 151-3363-1133

Landline: 0757-88048677

Email: 731731188@qq.com

Guozong Aluminum

Address 1: zhifangkou bridge, Zoushi Town, Taoyuan County, Changde City, Hunan Province

Address2: No. 28, North of Chatian Street, Shishan Town, Nanhai District, Foshan City

Scan, WeChat Consulting