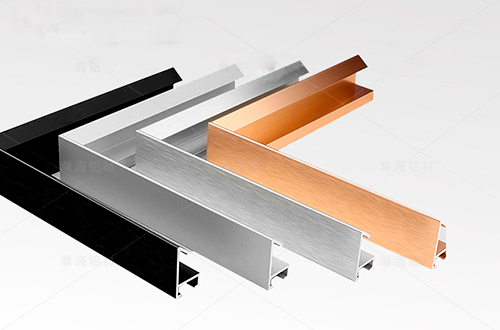

Years of concentration

Advertising aluminum profile

Extruded frame aluminum due to the diversity of its production process, the hot extrusion process the aluminum surface due to frame processing conditions directly indirectly caused by molds has the following problems polishing quality: coarse grain, color separation , Dark bands, bright bands, crossed lines, raised bone (concave bone, convex bone), poor finish.

Causes of rough surface defects of extruded picture frame aluminum: In the extrusion manufacturing of picture frame aluminum, the usual problems are relatively straightforward, such as bending, twisting, deformation, slag inclusion, etc. The aluminum frame of the picture frame coming out the extrusion line is called base material blank white material. The initial judgment of the surface quality of the aluminum frame is usually when the mold is pressed to 2-3 rods after the machine is installed. The first sample is taken to determine whether the surface quality is acceptable. After the surface is qualified, other items are inspected. Method for judging the surface quality defects of aluminum profile blanks:

1. Feeling touch: touch the surface of the substrate with your hand, the scribe line that can be pulled with your nails, you can feel the concave bone convex bone, judge whether there is a clear feel. Suitable for various surface treatments.

2. Pencil scratches: Scratch the surface of the aluminum profile with a pencil during the extrusion process of the aluminum profile. Use the feel the continuity of the pencil scratches to determine whether there are rough lines. The scribe grooves are suitable for the surface determination of oxide materials.

3. Spray paint test: When sampling for the first inspection, spray the surface of the substrate with automatic spray paint to simulate the spray effect. After the surface is dry for 1-2 minutes, observe judge whether there are defects such as scribe, concave bone, convex bone so on. Suitable for spray coating surface determination.

4. Alkali washing test: When sampling in the first inspection, take a 300mm sample section on the third rod, soak it in the pot mold for 30-40 seconds, (note: the concentration of the alkaline solution the tank temperature, if the concentration, the tank temperature is too low, Properly extend the immersion time, generally more than 60 seconds) Through the surface of the substrate after alkali washing, you can see whether there are defects such as color separation, scribing, die bonding line. Suitable for oxidizing materials with high surface requirements.

Mobile phone: Mr. Yao: 151-3363-1133

Landline: 0757-88048677

Email: 731731188@qq.com

Guozong Aluminum

Address 1: zhifangkou bridge, Zoushi Town, Taoyuan County, Changde City, Hunan Province

Address2: No. 28, North of Chatian Street, Shishan Town, Nanhai District, Foshan City

Scan, WeChat Consulting