Years of concentration

Advertising aluminum profile

When the aluminum extrusion press is pressurized, air will remain in the aluminum profile, causing air bubbles to appear inside on the surface of the aluminum profile, resulting in defects that cannot be completely solved, making the aluminum profile a waste. In order to prevent air entering the aluminum profile, it is necessary to find out why the air is brought in. The following author introduces the main factors of the residual air in the four extruded aluminum profiles.

1. Hot shearing of long rods causes residual air. The shear surface formed during thermal shearing of the rod is very good vertical. Industrial aluminum profiles simply undergoing hot shearing of long rods can cause severe bending of the rods, resulting in an oval-shaped cross-section of the aluminum profile a very large rounded corner being cut off. Even if it is a new type of long-bar hot shear, the angle of the edge of the bar being sheared will always produce rounds. These rounds are a good place for air residue.

2. Upsetting results in residual air. Only when the diameter of the cylinder containing the aluminum ingot is larger than the diameter of the rod, can the rod be put into the cylinder containing the aluminum ingot. After pressure is applied to the rods in the aluminum ingot cylinder, which causes the rods to expand to the diameter of the ingot cylinder, the gas carried must be discharged. The gas is exhausted will remain in the aluminum ingot later become air bubbles.

3. Residual air due to the contact of two aluminum rods. Because the surface of the two short rods is basically flat, the probability of carrying in the air is very small. The quality of the sawing directly interferes with the amount of air carried between the two short rods. At present, there is a new high technology that can prevent two short rods contacting each other eliminate the possibility of air ingress.

4. When advertising aluminum profiles are extruded, it is necessary to avoid the entry of air, so as to avoid the situation of air residue, which is caused by various defects in the post-processing.

Mobile phone: Mr. Yao: 151-3363-1133

Landline: 0757-88048677

Email: 731731188@qq.com

Guozong Aluminum

Address 1: zhifangkou bridge, Zoushi Town, Taoyuan County, Changde City, Hunan Province

Address2: No. 28, North of Chatian Street, Shishan Town, Nanhai District, Foshan City

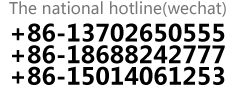

Scan, WeChat Consulting