Years of concentration

Advertising aluminum profile

The extrusion method in which the product flows out in the same direction as the extrusion axis during the extrusion process of the aluminum frame is called forward extrusion. Forward extrusion is the most basic method. With its mature technology, simple process operation, large production flexibility, products with excellent surfaces, it has become one of the widely used methods in aluminum frame aluminum molding. Forward extrusion can be divided into plane deformation extrusion, axisymmetric deformation extrusion general three-dimensional deformation extrusion, cold extrusion, warm extrusion hot extrusion.

The basic characteristics of positive extrusion are: relative sliding occurs between the aluminum frame of the picture frame the extrusion tube during extrusion, there is a large external friction, in most cases, this friction is harmful, it Uneven metal flow, which adversely affects the quality of the extruded picture frame aluminum, leading to uneven structure performance of the head tail, surface layer center of the extruded picture frame; increases the energy consumption of the extrusion In general, the frictional energy consumption on the inner surface of the extrusion cylinder accounts for 30-40% of the energy consumption of the extrusion, even higher; due to the strong frictional heating effect, the extrusion of aluminum aluminum alloys with low medium melting points is limited The increase in speed has accelerated the wear of the extrusion die.

The extrusion method classified according to the direction is mainly based on whether the running direction of the extrusion shaft is opposite to the same as the direction of movement of the aluminum product. If the directions are the same, it means that the aluminum profile is forward extrusion. Forward extrusion is a fairly basic method, because this extrusion method is simple to operate, relatively flexible, has a smooth extrusion surface. The technology is more mature used more in the processing of aluminum aluminum alloy materials.

What needs to be paid attention to during positive extrusion is that the sliding between the aluminum profile the extrusion cylinder during extrusion will cause a large sliding friction, this friction is conducive to the extrusion of aluminum products in most cases. Because this will make the aluminum product's moving speed constant, resulting in uneven stress on all parts of the aluminum product, the quality of the final extruded aluminum profile will be uneven; under the effect of friction alone, Friction will generate heat. As the relative speed between the extrusion of the aluminum product the mold wall will increase, the wear of the mold will also increase, the life will be reduced accordingly.

Mobile phone: Mr. Yao: 151-3363-1133

Landline: 0757-88048677

Email: 731731188@qq.com

Guozong Aluminum

Address 1: zhifangkou bridge, Zoushi Town, Taoyuan County, Changde City, Hunan Province

Address2: No. 28, North of Chatian Street, Shishan Town, Nanhai District, Foshan City

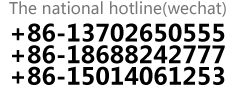

Scan, WeChat Consulting