Years of concentration

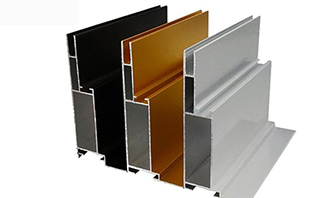

Advertising aluminum profile

Frame aluminum processing every aspect, manufacturers have to rationalize the process, we can better enhance the utilization of materials efficient to reduce frame aluminum cast loss, that frame our aluminum manufacturers In other words, what can we do to effectively reduce the loss of aluminum materials?

I. During the production of picture frame aluminum materials, strictly follow the process requirements to ensure that the qualified rate of each process of aluminum materials is high. Especially in the process of processing ordinary aluminum, try to avoid the occurrence of defective aluminum such as flash, burrs, weight mismatches. .

In the process of processing picture frame aluminum, we must make full contact with oxygen, reduce the contact time of liquid aluminum oxygen, meet the conditions of processing, as soon as possible to change the liquid aluminum in the furnace The finished product reduces the oxidation time in the manufacturing process.

3. There are many processing links for picture frame aluminum materials. At this moment, reasonable processing time should be planned to ensure the quality of the processing save losses in the manufacturing process.

In the process of casting aluminum rods in the aluminum frame, the metal elements structures in the aluminum rods are uneven. In addition, there are usually residual stresses in the aluminum rods. The inhomogeneity of the ingot changes the pressure processing technology of the ingot some characteristics of the aluminum frame. It is necessary to carry out the uniform treatment of the ingot, which is carried out in a homogenizing furnace.

The hot air circulation system of the homogeneous furnace uses multiple fans with large air volume in series to ensure that the temperature difference in the furnace is extremely small. The heating system of the homogeneous furnace uses multiple nozzles multiple points for heating. The combustion of the nozzles is controlled proportionally to ensure that the combustion is complete the temperature in the furnace is uniform. The loading unloading of the homogenizing furnace is completed by a composite three-dimensional material cart. The composite three-dimensional material cart can operate in six directions: front, back, left, right, up, down. The cooling system of the homogenizing furnace is closely combined with water cooling air cooling. The aluminum frame of the picture frame achieves a very good cooling effect at a low cost.

Mobile phone: Mr. Yao: 151-3363-1133

Landline: 0757-88048677

Email: 731731188@qq.com

Guozong Aluminum

Address 1: zhifangkou bridge, Zoushi Town, Taoyuan County, Changde City, Hunan Province

Address2: No. 28, North of Chatian Street, Shishan Town, Nanhai District, Foshan City

Scan, WeChat Consulting